Looking for trusted, quality oilfield equipment?

We’ve got the drilling equipment you need.

Call our experts today at 936-336-5154.

We Save You Money

New and Used Equipment

International Buyer and Seller

REQUEST A QUOTE

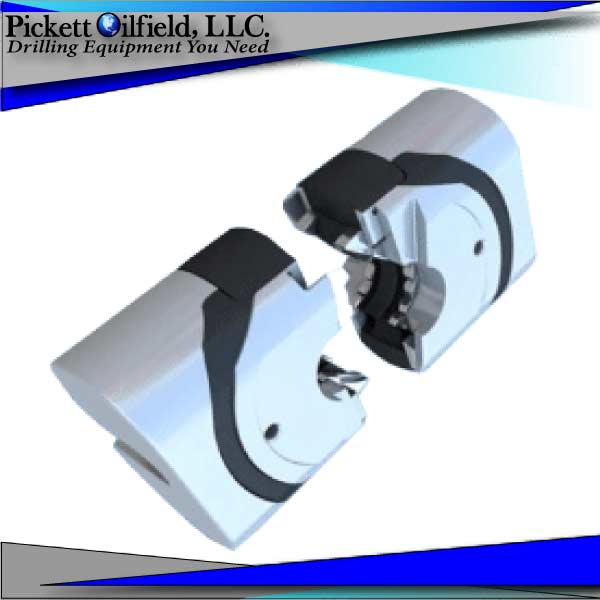

What to consider when buying a BOP?

If you are searching for OEM/API certified BOPs (Blowout Preventers), you should be familiar with the type required. There are many types:

- Annular – used to close around the drill string, casing or a non-cylindrical object.

- Single Ram – with this type, you should know what size outlets are required and if you need standard or shear bonnets.

- Double Ram – with this type, you need to know the same information as the single ram.

You should also have a timeframe in which you need the items procured. Most purchases are required immediately while some are long-term. It is also critical to know the country of final destination for the blowout preventer.

PickettOilfield.com provides our customers with a wide-ranging selection of quality Blowout Preventers and Ram Blocks to select from with competitive pricing. Click through our inventory of Blowout Preventers and BOP parts to find sales and competitive rates. Click here.

How much does a blowout preventer cost?

Pricing, of course, varies with the different sizes and working pressures for BOPs. You can also buy a used, remanufactured or brand new blowout preventer and these will have different price ranges as well. For specific pricing information, contact Pickett Oilfield, LLC at: Phone: 936-336-5154 Email: Sales@PickettOilfield.com.

How do blowout preventers work?

They are used on the wellhead as a safety precaution, so that if the well attempts to blowout, it can be controlled. Most of them today are hydraulically operated. Essentially, a blowout preventer (BOP) shuts off the valve heading below the equipment to halt any liquid from appearing in a dangerous explosion, or a kick. A specific level of containment must be sustained while working with the mud and materials that could create breaks in the flow of extraction. There are numerous features in a BOP that make up the whole and two kinds of valves that assist the apparatus in case there is a bad kick.

An annular BOP closes the space around the width of the pipe. The actual system cannot be closed with a valve because of the drill string, so the annular controls the air flow for the mud without cutting off any other systematic elements. The annular BOP provides the most efficient airtight option and is put on the top of the BOP stack. A RAM BOP also works to thwart any unwanted materials from exploding in the system. Several at a time are used in the BOP stack to safeguard optimal safety.

Competitive Rates Available at Pickettt Oilfield, LLC.

Ready to make the call?

Pickettt Oilfiled is ready to answer.

200378 US HWY 90 E

P.O. Box 5048

Liberty, TX 77575

Sales@PicketttOilfield.com

Telephone

936-336-5154

Fax

936-336-3434